What are our main printing methods?

- Offset printing: This is the most common printing method, suitable for printing various flat media such as posters, brochures, and magazines.

- Digital printing: This is a digital printing method, suitable for small batch and personalized printing needs, such as business cards, flyers, and personalized books.

- Gravure printing: This is a high-quality printing method, suitable for printing products with high requirements, such as packaging boxes, greeting cards, and tickets.

- Screen printing: This is a printing method commonly used for printing textiles and flat media, suitable for printing T-shirts, posters, and flags.

What are the advantages and disadvantages of the main printing methods?

1. Offset printing

The advantage of offset printing is that it has relatively low cost and is suitable for large volume printing needs. However, it may not be suitable for personalized and small batch printing.

Why is offset printing not suitable for personalized and small batch printing?

The reason offset printing is not suitable for personalized and small batch printing is that it usually requires the use of printing plates to transfer images or text, which requires additional time and cost to prepare and produce the plates. For personalized and small batch printing needs, each design may be different and requires the production of multiple different printing plates, which will increase time and cost. In contrast, digital printing can directly print the desired design from a computer or digital file, making it more suitable for personalized and small batch printing needs with faster delivery times.

2. Digital printing

The advantage of digital printing is that it enables personalized and small batch printing, and has faster delivery times. However, it may not be suitable for large volume printing needs and has higher costs.

Why can digital printing achieve personalized and small batch printing?

The reason digital printing can achieve personalized and small batch printing is that it utilizes digital technology to directly print the desired design from a computer or digital file, without the need to create and prepare printing plates. This allows each design to be unique and easily adjusted and modified as needed. Digital printing has faster delivery times and is suitable for personalized and small batch printing needs that require quick production and delivery.

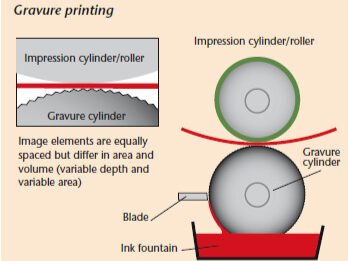

3. Gravure printing

The advantage of gravure printing is that it can achieve high-quality printing effects and is suitable for products with high requirements. However, the equipment and operation costs of gravure printing are higher.

Why can gravure printing achieve high-quality printing effects?

Gravure printing can achieve high-quality printing effects because of the following characteristics:

- High resolution: Gravure printing uses printing plates with high resolution, which can accurately transfer images and details, resulting in clear and sharp printing effects.

- Rich colors: Gravure printing can use various colors and inks, including metallic inks and special effect inks, making the printed materials colorful and diverse.

- High precision: Gravure printing equipment has a high-precision control system, which can accurately control the distribution and coverage of ink, achieving precision and consistency in printed materials.

- Outstanding texture: Gravure printing can achieve various special effects such as embossing and hot stamping, giving the printed materials a unique texture and tactile sensation.

In summary, gravure printing, with its high-resolution printing plates, use of various colors and inks, precision control, and special effects, can achieve high-quality printing effects, making it suitable for products and projects that require high printing quality.

4. Screen printing

The advantage of screen printing is that it is suitable for printing various materials and media, including textiles and flat media. However, screen printing may not be suitable for complex patterns and details.

Why is screen printing suitable for printing various materials and media, including textiles and flat media?

- Versatility: Screen printing can use different types of inks to meet the printing needs of different materials and media. Whether it is textiles, plastics, metals, or glass, screen printing can achieve durable and vibrant printing effects on their surfaces.

- Thick coatings: Screen printing can achieve thicker coatings, giving the printed materials a better texture and tactile sensation. This makes screen printing particularly suitable for products that require increased material thickness or texture, such as textiles like T-shirts and flags, as well as posters and billboards.

- Durability: Screen printing inks have strong durability and resistance to wear, enduring multiple washings and uses. This makes screen printing suitable for products that require long-term use or frequent exposure to external environments, such as outdoor signage and car stickers.

- Adaptability: Screen printing can adapt to different shapes and sizes of printing objects, whether they are flat or curved. This allows screen printing to achieve complex patterns and designs on various products, such as flat advertisements, decorative items, and crafts.

In conclusion, the versatility, thick coatings, durability, and adaptability of screen printing make it a widely used printing method for various materials and media, especially suitable for printing needs in textiles and flat media.