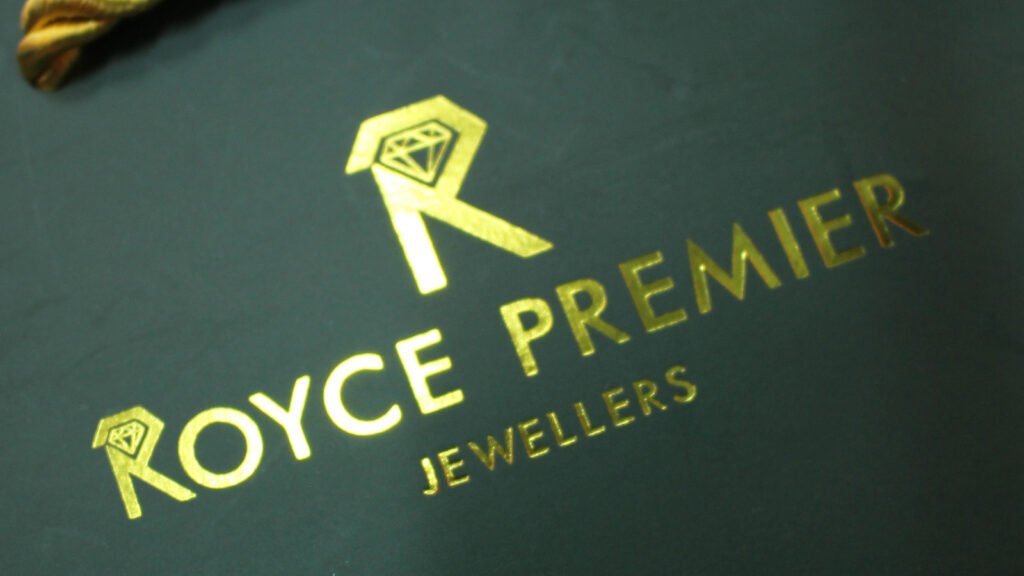

Hot foil stamping is a premium printing technique that involves applying metallic or pigmented foil to a surface using heat and pressure. This method is widely used to add a luxurious, high-quality finish to printed materials, creating a visually striking and tactile effect. Here is a detailed overview of hot foil stamping:

Benefits of Hot Foil Stamping

- Luxurious Appearance:

- Metallic Shine: The foil’s metallic sheen adds a high-end, luxurious look to printed materials, making them stand out.

- Variety of Finishes: Foils are available in various colors and finishes, including gold, silver, holographic, matte, and gloss, allowing for diverse design possibilities.

- Durability:

- Long-Lasting: The foil is durable and resistant to fading, ensuring the longevity of the printed material’s visual appeal.

- Scratch Resistance: The foil layer provides some protection against scratches and scuffs.

- Enhanced Perception:

- Professional Quality: The use of hot foil stamping conveys a sense of quality and professionalism, enhancing the perceived value of the product.

- Tactile Experience: The raised foil adds a tactile dimension, providing a pleasing touch that can engage recipients.

- Versatility:

- Wide Range of Applications: Suitable for various materials, including paper, cardstock, leather, and plastic, making it a versatile choice for many projects.

Applications of Hot Foil Stamping

- Business Cards: To create a memorable, high-impact first impression.

- Brochures and Flyers: Adding foil accents to highlight important information or design elements.

- Book Covers: Enhancing the aesthetic appeal of books, especially for special editions and high-end publications.

- Packaging: Used in luxury product packaging to attract customers and convey a premium quality.

- Labels and Tags: For product labeling that stands out on shelves.

- Invitations and Greeting Cards: To add a touch of elegance and sophistication to special occasions.

Process of Hot Foil Stamping

- Design Preparation: A design is created and transferred to a metal die or plate. This die is engraved with the desired pattern, text, or image.

- Foil Selection: Choose the appropriate foil type and color for the project.

- Heating: The metal die is heated to the required temperature.

- Stamping: The foil is placed between the die and the substrate (e.g., paper, cardstock). The heated die is pressed onto the foil, which transfers the design to the substrate through a combination of heat and pressure.

- Cooling and Inspection: The stamped material is allowed to cool, and the finished product is inspected for quality and consistency.

- Additional Finishing: The stamped material may undergo additional processes such as embossing, debossing, or lamination to enhance the final product.

Considerations for Hot Foil Stamping

- Cost: Hot foil stamping can be more expensive than other printing techniques due to the specialized materials and processes involved.

- Design Complexity: Detailed and intricate designs may require more precise dies and higher quality control, which can affect the overall cost and production time.

- Substrate Compatibility: Ensure the substrate material is suitable for hot foil stamping. Some materials may not respond well to heat and pressure.

- Environmental Impact: Consider using eco-friendly foils and substrates to reduce the environmental impact.

Hot foil stamping is an excellent choice for projects that require a high-quality, luxurious finish. It is particularly effective for business cards, brochures, book covers, packaging, and special event invitations, providing a unique combination of visual appeal and tactile experience that enhances the perceived value of the printed material.