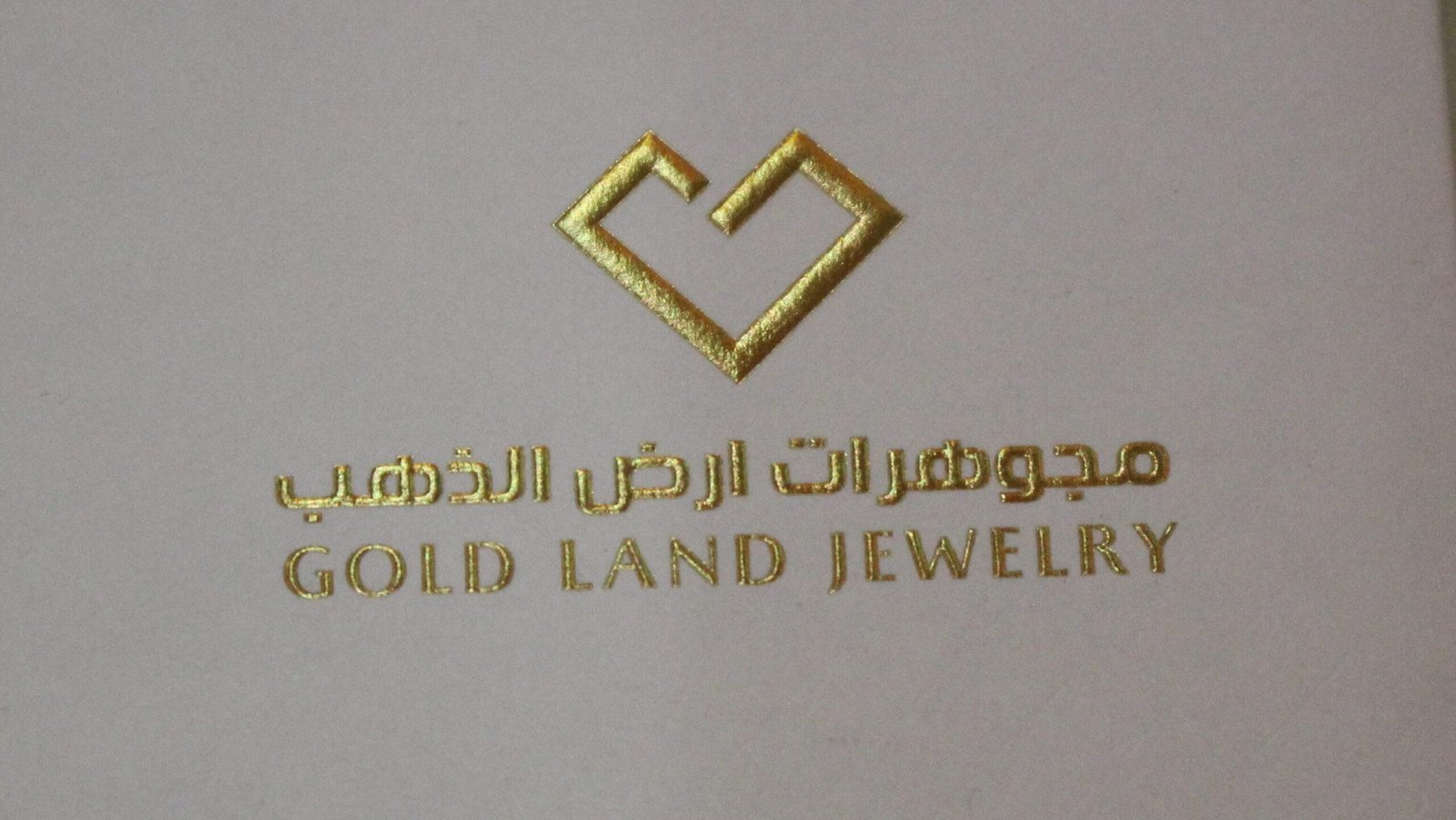

Combination embossing is a specialized finishing technique used in printing and packaging to create raised or recessed areas on the surface of a substrate, often in combination with other effects such as foil stamping or printing. This method allows for intricate and visually striking designs that add texture and dimension to printed materials. Here’s a detailed overview of combination embossing:

Benefits of Combination Embossing

- Enhanced Visual Appeal:

- Texture and Dimension: Creates raised or recessed areas on the substrate, adding depth and tactile interest to the design.

- Attention-Grabbing: Embossed elements stand out visually and can attract attention to key areas of the printed material.

- Versatility:

- Compatibility with Other Effects: Combination embossing can be combined with other finishing techniques such as foil stamping, printing, or spot UV coating to achieve unique and visually appealing results.

- Customization: Offers flexibility in design, allowing for the creation of custom patterns, textures, and effects tailored to specific branding or design requirements.

- Perceived Quality:

- Professional Finish: Gives printed materials a high-quality, premium look and feel, enhancing the overall perceived value of the product.

- Brand Enhancement: Reinforces brand identity and messaging by adding a distinctive and memorable tactile element to marketing materials and packaging.

Applications of Combination Embossing

- Packaging: Used in product packaging to create eye-catching designs and enhance shelf appeal.

- Labels and Tags: Adds a tactile element to product labels and tags, making them stand out on store shelves.

- Business Cards: Provides a unique and memorable tactile experience that leaves a lasting impression on recipients.

- Invitations and Stationery: Elevates the elegance and sophistication of event invitations, greeting cards, and personalized stationery.

- Book Covers: Adds texture and visual interest to book covers, making them more attractive to readers.

Process of Combination Embossing

- Design Preparation: The desired design is created, specifying areas for embossing, debossing, and any additional effects.

- Embossing Plate Creation: Metal dies or plates are created based on the design specifications for embossing and debossing.

- Embossing: The substrate is placed between the embossing plates and pressed under high pressure, creating raised areas (embossing) and/or recessed areas (debossing) on the surface.

- Additional Effects: Combination embossing can be combined with other effects such as foil stamping, printing, or spot UV coating to enhance the design further.

- Quality Inspection: The finished product is inspected to ensure that the embossed elements meet quality standards and specifications.

Considerations for Combination Embossing

- Design Complexity: Intricate designs may require multiple embossing plates and careful registration to achieve the desired result.

- Substrate Selection: The choice of substrate can impact the effectiveness of combination embossing. It’s essential to select materials that can withstand the embossing process without tearing or distorting.

- Cost and Production Time: Combination embossing can be more expensive and time-consuming than other finishing techniques due to the need for specialized equipment and skilled labor.

- Design Intent: Consider the intended effect and overall design aesthetic when incorporating combination embossing into printed materials.

Combination embossing is a versatile and effective finishing technique that adds texture, dimension, and visual interest to printed materials. Whether used in packaging, labels, business cards, or invitations, it provides a unique and memorable tactile experience that enhances the overall quality and appeal of the product.